We offer precision and productive laser cutting solutions with over 8 years of experience in metal fabrication.Your trusted partner for high-quality laser cutting and metal fabrication.

Contact with

us for any

soluton

Call Anytime

+91-86829 25014

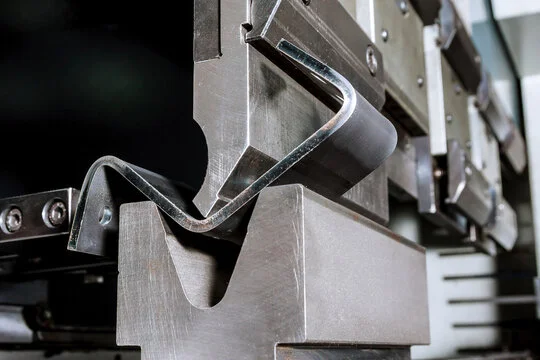

Our Bending & Folding service delivers high-precision sheet metal forming using advanced CNC press brake technology. With automated controls, modern tooling, and skilled operators, we ensure every bend meets the required angle, tolerance, and consistency.Whether it’s a simple single bend or a complex multi-bend component, our process guarantees accuracy, repeatability, and clean finishing.

Bending and folding are essential processes in modern sheet metal fabrication, enabling accurate shaping and forming of metals for diverse industrial applications.

At SPM Laser Services, we use Computer Numerical Control (CNC) bending machines to ensure high precision, consistency, and productivity in every job.

CNC bending offers exceptional dimensional accuracy and design flexibility, making it suitable for industries like automotive, chemical processing, furniture manufacturing, shipbuilding, railways, construction, and many more. With automation at the core, this process reduces manual errors and provides faster, cost-effective production.

Key Features

Our CNC Press Brake machines are engineered to deliver superior bending performance, ensuring each component meets the highest quality standards.

High productivity with 1.3x table speed and 3x back gauge speed

Supports height tools and advanced supporters

Reduced wastage, ensuring economic manufacturing and quick delivery

High-level process simulation for collision detection.

What materials can you bend and fold using your CNC press brake machines?

We work with Mild Steel (up to 12mm), Stainless Steel (up to 10mm), and Aluminum, forming them into brackets, frames, enclosures, channels, and various industrial components with high precision and clean finishing.

How accurate are your bending and folding services?

Our CNC press brake machines use advanced software, bend simulation, back-gauge systems, and direct angle control, ensuring every bend is dimensionally accurate, repeatable, and free from distortion. Each part is checked for perfect angle consistency and tolerance.

Do you handle both custom jobs and bulk production?

Yes. We handle single custom components, medium-sized batches, and large production runs. With 200 tons ram capacity and 3-meter bending length, our machines support a wide range of industrial requirements while maintaining high speed and consistency.

How do you ensure quality in the bending process?

Our trained operators evaluate material thickness, grain direction, tooling selection, bend sequence, and design requirements before processing. Every component undergoes careful inspection to ensure accuracy, stability, and smooth finishing.