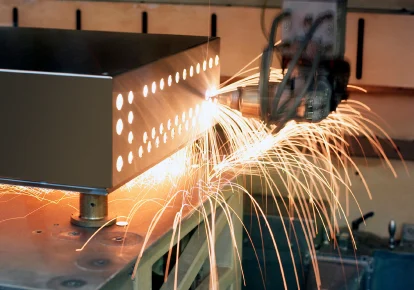

We offer precision and productive laser cutting solutions with over 8 years of experience in metal fabrication.Your trusted partner for high-quality laser cutting and metal fabrication.

Contact with

us for any

soluton

Call Anytime

+91-86829 25014

Sheet metal fabrication is a core industrial process that transforms raw metal sheets into functional, reliable, and precisely engineered components. It involves cutting, bending, forming, and assembling metals to create a wide range of products used in industries such as construction, automotive, electrical, machinery, and engineering.

With a combination of advanced machinery and highly trained technicians, we ensure that every component we fabricate meets strict quality standards, offering both durability and a superior finish.

Using laser cutting and shearing techniques to achieve clean, accurate shapes without distortion.

CNC press brakes ensure perfect angles, seamless bends, and repeatability for large batch production.

Our fabrication process is designed to deliver accuracy and consistency across all project sizes—whether it’s a simple part or a complex custom structure. We follow a systematic workflow to ensure smooth production from start to finish.

We Offer the Following Welding Services:

Our welds are not only strong but also neat, ensuring that the finished products meet both performance and aesthetic expectations.

MIG Welding

TIG Welding

ARC Welding

What types of sheet metals do you work with?

We fabricate components using Mild Steel, Stainless Steel, Aluminum, Galvanized Iron, and other industrial-grade metals. Each material is processed with the appropriate cutting, bending, and welding techniques for the best results.

Do you handle both small and large production orders?

Yes. We support single custom parts, prototypes, and full-scale bulk production. Our advanced CNC machines and skilled technicians ensure consistent accuracy across all batch sizes.

What welding services do you offer for fabrication?

We provide MIG, TIG, and ARC welding using premium equipment from Fronius, Lorch, and L&T. Our welders ensure strong joints, clean finishes, and high structural reliability.

How do you ensure quality and accuracy in fabricated components?

Each product goes through a controlled process: precision cutting, CNC bending, accurate forming, expert welding, and final inspection. We verify dimensions, structural strength, and overall finish before dispatch to ensure top-quality results.