We offer precision and productive laser cutting solutions with over 8 years of experience in metal fabrication.Your trusted partner for high-quality laser cutting and metal fabrication.

Contact with

us for any

soluton

Call Anytime

+91-86829 25014

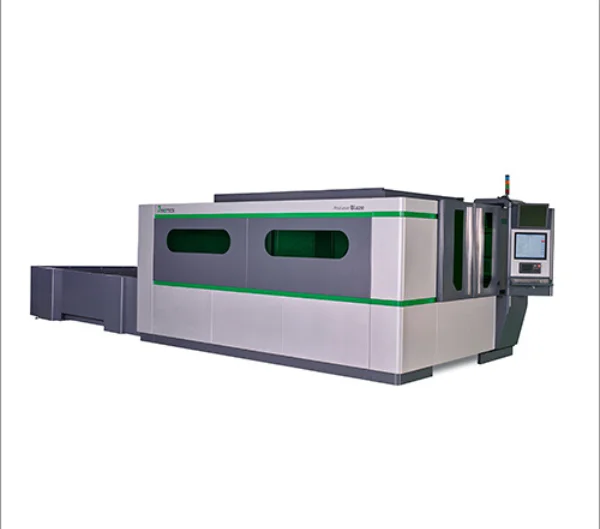

The Proteck S3030 Laser Cutting Machine is a state-of-the-art fiber laser system engineered for accuracy, speed, and reliability. Designed for modern manufacturing environments, this machine offers superior performance for cutting a wide variety of metals with exceptional precision. Whether you are in fabrication, engineering, automotive, or custom metal design, the Proteck S3030 delivers the cutting-edge technology needed to improve productivity and maintain top-notch quality.

With a powerful 3 kW fiber laser source and a spacious 3000 × 1500 mm bed size, the Proteck S3030 is built to handle both large sheet materials and intricate part geometry.

Its advanced motion control system ensures smooth operation, high accuracy, and consistent repeatability.

The machine is equipped with intelligent features that enhance performance, reduce downtime, and minimize operating costs.

Applications Across Industries

The Proteck S3030 is widely used in:

Sheet Metal Fabrication

Automotive and Transport Industry

Machinery and Industrial Equipment Manufacturing

Electrical Cabinets and Enclosures

What types of materials can the Proteck S3030 laser cutting machine handle?

The Proteck S3030 can efficiently cut a wide range of metals including Mild Steel (up to 20 mm), Stainless Steel (up to 10 mm), Aluminium (up to 10 mm), Brass (up to 10 mm), and GI sheets (up to 6 mm), making it suitable for diverse industrial applications.

How does the fiber laser technology improve cutting quality?

Fiber laser technology produces a stable, fine beam that ensures extremely clean edges with minimal heat-affected zones. This results in smooth, precise cuts and reduces the need for post-processing.

Is the Proteck S3030 suitable for high-volume production?

Yes. With its advanced motion control system, high-speed drives, and 3000 × 1500 mm working area, the Proteck S3030 is designed for fast cutting cycles, consistent repeatability, and high productivity—ideal for mass production environments.

What are the maintenance requirements for this machine?

The Proteck S3030 requires low maintenance due to its fiber laser technology, fewer moving parts, and robust frame. It offers long service life, reduced downtime, and cost-effective operation compared to traditional CO₂ laser systems.